What is 5S & Why is it Important?

In today’s competitive market it’s imperative now more than ever to operate at peak efficiency with minimal interruptions in production and service. Companies must adopt Lean principles such as 5S, which focuses on the elimination of wastes, creates cost savings while maintaining a healthy safe environment for your employees.

5S is a simple method to ensure that workspaces and resources are arranged and maintained in an orderly safe manner to reduce waste. The 5S system is part of Toyota’s Lean Manufacturing methodology designed to reduce waste within a facility.

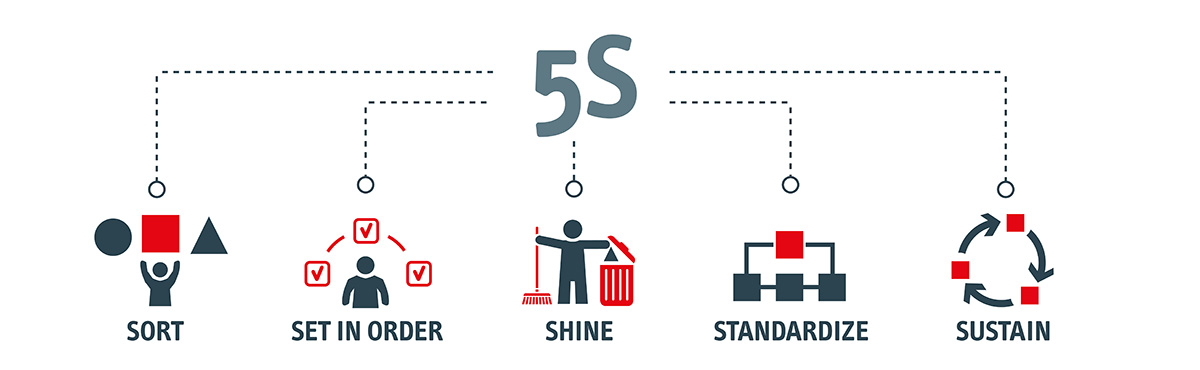

Here are the 5 Steps to Operational Stability:

![]() Sort (Seiri): When In Doubt, Move It Out – Start by removing all items from your work area. Inspect the equipment and identify those items that are critical to the success of the function performed at the workstation. Eliminate any duplicates, unnecessary equipment, infrequently used items and trash. Identify the non-essential items as either waste or “valuable but not critical.” Store the non-critical items outside of the workstation area. This saves time, space and labor costs, while enhancing productivity.

Sort (Seiri): When In Doubt, Move It Out – Start by removing all items from your work area. Inspect the equipment and identify those items that are critical to the success of the function performed at the workstation. Eliminate any duplicates, unnecessary equipment, infrequently used items and trash. Identify the non-essential items as either waste or “valuable but not critical.” Store the non-critical items outside of the workstation area. This saves time, space and labor costs, while enhancing productivity.

![]() Set in Order (Seiton): A Place For Everything & Everything In Its Place – Whatever equipment is deemed critical to the operation must now be organized. Assign positions for all equipment, work in progress and raw materials, keeping ease of reach, identification and proximity to work surface in mind. The goal is to maximize the efficiency of the workstation layout. The most frequently used tools should be the most convenient to grab. This eliminates wasted time from excess motion and searching. This principle is especially important in the aerospace and defense industry, where delays, misplaced tools or inconsistent workflows can directly impact production schedules and regulatory compliance. Maintaining a well-ordered environment, often supported by cloud ERP software, enhances efficiency and reinforces the high standards of precision and accountability required in these operations.

Set in Order (Seiton): A Place For Everything & Everything In Its Place – Whatever equipment is deemed critical to the operation must now be organized. Assign positions for all equipment, work in progress and raw materials, keeping ease of reach, identification and proximity to work surface in mind. The goal is to maximize the efficiency of the workstation layout. The most frequently used tools should be the most convenient to grab. This eliminates wasted time from excess motion and searching. This principle is especially important in the aerospace and defense industry, where delays, misplaced tools or inconsistent workflows can directly impact production schedules and regulatory compliance. Maintaining a well-ordered environment, often supported by cloud ERP software, enhances efficiency and reinforces the high standards of precision and accountability required in these operations.

![]() Shine (Seiso): A Clean Workplace Enhances Quality, Safety & Pride – Keep everything clean, every day. Doing this keeps things ready to be used when needed. A clean workspace is a productive workspace, and Seiso literally means “to clean or shine.” Clean the floors, the walls and the equipment and ensure all items are restored to their designated place. Make sure the workstation is well lit. This should be a part of your daily tasks and should not be postponed until idle time is available.

Shine (Seiso): A Clean Workplace Enhances Quality, Safety & Pride – Keep everything clean, every day. Doing this keeps things ready to be used when needed. A clean workspace is a productive workspace, and Seiso literally means “to clean or shine.” Clean the floors, the walls and the equipment and ensure all items are restored to their designated place. Make sure the workstation is well lit. This should be a part of your daily tasks and should not be postponed until idle time is available.

![]() Standardize (Seiketsu): Standards Exist & Are Being Followed – Ensure conditions of the work area do not return to the original, disorganized state. Make the previous three S’s part of your standard procedures each day. Implement them with the help of signs, banners, shadow boards, tool holders, etc. Make sure all workers understand their responsibilities and are empowered to perform all of the tasks. This level of discipline is especially valuable in highly complex industries such as oil and gas, where unstructured or inconsistent work environments can contribute to safety risks and operational downtime. Reinforcing daily standards helps crews stay aligned and ensures that high-pressure, high-risk work sites continue to operate smoothly and safely.

Standardize (Seiketsu): Standards Exist & Are Being Followed – Ensure conditions of the work area do not return to the original, disorganized state. Make the previous three S’s part of your standard procedures each day. Implement them with the help of signs, banners, shadow boards, tool holders, etc. Make sure all workers understand their responsibilities and are empowered to perform all of the tasks. This level of discipline is especially valuable in highly complex industries such as oil and gas, where unstructured or inconsistent work environments can contribute to safety risks and operational downtime. Reinforcing daily standards helps crews stay aligned and ensures that high-pressure, high-risk work sites continue to operate smoothly and safely.

![]() Sustain (Shitsuke): Make a habit of properly maintaining correct procedures to avoid backsliding. Implementing these steps is a continuous process. It is important to ensure that they are done each day to prevent slipping into old behaviors. Commit to performing these steps every shift and make sure that any changes to your product or process are compensated for at your workstation and problems are alleviated as quickly as they are created.

Sustain (Shitsuke): Make a habit of properly maintaining correct procedures to avoid backsliding. Implementing these steps is a continuous process. It is important to ensure that they are done each day to prevent slipping into old behaviors. Commit to performing these steps every shift and make sure that any changes to your product or process are compensated for at your workstation and problems are alleviated as quickly as they are created.

With the successful reduction of wastes, productivity naturally improves, and most often companies experience up to a 60% increase in productivity. Reviewing processes and optimizing them for efficiency means you get more work done in less time and capacity can increase by 30% or higher. Being well-organized and clutter-free lowers the risks of workplace accidents and employees come to work every day with greater pride and satisfaction.

Here are some of the key questions industry leaders can ask when implementing 5S into their operations:

Q: How does 5S improve productivity?

A: By reducing waste and optimizing processes, companies often see up to a 60% increase in productivity and a 30% or more increase in capacity. Work gets done faster, with fewer inefficiencies.

Q: What are the safety and morale benefits of 5S?

A: A clean, organized workplace lowers the risk of accidents and improves employee pride, satisfaction, and engagement.

Q: What types of organizations can benefit from 5S?

A: 5S is used across manufacturing, healthcare, service industries, military, government, and finance. Its flexible, repeatable approach fits nearly any environment.

Q: What physical changes result from 5S implementation?

A: 5S typically leads to reduced space requirements, with clearly labeled tools, optimized storage, and less time wasted searching for items.

Q: Why is 5S considered a foundational strategy?

A: It creates an environment where employees can do their best work, supporting other operational strategies through improved organization and respect for the workplace.

5S has been widely used in all types of organizations, from manufacturing and service to health care; from military and government to financial institutions and works well with all other strategies because it is a repeatable set of concepts that can be applied to almost any environment. The end result of a 5S implementation is also a significant reduction in the space needed to perform the work. Tools and material needed to perform the job are labeled and stored appropriately. Shelving and racks are optimized in a smaller footprint, eliminating the need to search for items. When employees have what they need, when they need it, work related stressors decrease and respect for the workplace, company and others increase.

The answer to the question – “Why Implement 5S?” is easy, you are…creating an environment where people can do their best work!

Check out our 5S Organization & Discipline Workshop to lean more.

FAQs

Why is 5S important for manufacturers and other organizations?

5S is important because it drives operational stability and efficiency. By ensuring tools, equipment, and resources are properly organized, businesses reduce wasted time searching for items, improve safety, and minimize errors. A well-implemented 5S system can boost productivity by up to 67%, reduce production time, and cut workplace accidents. Beyond efficiency gains, 5S also creates a sense of ownership and accountability among employees, leading to higher morale and job satisfaction. It’s a strategy that benefits both the bottom line and workplace culture.

What are the five steps of 5S?

The five steps are:

- Sort – Remove unnecessary items from the workplace.

- Set in Order – Organize equipment and tools so everything has a designated place.

- Shine – Clean and inspect the workspace regularly to maintain safety and efficiency.

- Standardize – Establish clear rules and processes to sustain improvements.

- Sustain – Develop habits and accountability to ensure 5S becomes part of the culture.

Together, these steps create a cycle of continuous improvement that enhances productivity, safety, and quality.

How does 5S improve productivity?

5S improves productivity by reducing wasted motion, time, and space usage. When employees can quickly locate tools and materials, work flows more smoothly. Standardizing processes reduces variability, while regular cleaning and maintenance prevent breakdowns and delays. Studies show that companies adopting 5S can see up to a 67% increase in productivity. The methodology also creates a safer environment, minimizing disruptions caused by accidents or misplaced items. In short, 5S eliminates inefficiencies so employees can focus on value-added work.

How does 5S improve safety in the workplace?

A clean, organized, and standardized workplace significantly reduces hazards. By removing clutter and unnecessary items, 5S minimizes tripping risks and accidents. Properly labeled and stored tools ensure employees use the right equipment safely. Regular “Shine” activities highlight maintenance issues before they become safety threats. Additionally, clear standards and accountability reduce human error. Companies implementing 5S often report lower accident rates and improved compliance with safety regulations, making it not just a productivity tool but a vital safety strategy.

What are the business benefits of 5S beyond productivity?

Beyond productivity, 5S delivers cost savings, improved quality, stronger employee engagement, and better customer satisfaction. Reduced downtime and errors lead to fewer defects and faster delivery times. Optimized use of space may lower facility costs. Employees benefit from a more organized and less stressful environment, which boosts morale and retention. Customers ultimately receive higher-quality products delivered on time, strengthening trust and loyalty. In short, 5S creates a ripple effect that impacts the entire business ecosystem.

Which types of organizations can benefit from 5S?

While 5S originated in manufacturing, it applies to any industry. Service providers, healthcare facilities, military organizations, and even office environments have successfully implemented 5S to streamline operations. Any workplace that struggles with clutter, inefficiency, or inconsistent processes can benefit. Because it’s adaptable, 5S can be scaled to both small businesses and large enterprises, making it a universal method for improving workplace performance and culture.

What physical changes result from 5S implementation?

Organizations often see tangible changes such as decluttered workspaces, labeled storage areas, visual management systems, and standardized workstations. Walkways become clearer, tools are easier to find, and equipment is better maintained. These visible changes not only improve efficiency but also signal to employees and customers that the workplace values organization and quality. Over time, these physical transformations reinforce the cultural shift toward continuous improvement.

Why is 5S considered a foundational Lean strategy?

5S is foundational because it creates the environmental stability needed for other Lean initiatives to succeed. Lean practices such as Just-in-Time, Kaizen, and Total Productive Maintenance rely on organized, efficient workspaces. Without 5S, waste, delays, and inconsistencies can undermine Lean efforts. By establishing order, cleanliness, and accountability, 5S provides the groundwork for continuous improvement, making it the first step in many Lean transformations

How can WM Synergy help with 5S implementation?

WM Synergy supports organizations in adopting 5S through training, workshops, and consulting services. Our experts help assess your current operations, design a customized 5S program, and guide your team through each step of implementation. Beyond setup, we focus on sustaining results by embedding 5S into daily routines and linking it with broader Lean Manufacturing and ERP strategies. With decades of experience in operational excellence, WM Synergy ensures your 5S initiative delivers measurable improvements in productivity, safety, and employee engagement.