Stop Scheduling like It’s 1995: How to Improve On-Time Delivery in 2025 and Beyond

Production scheduling is one of the most critical processes in any manufacturing operation. Yet for many companies, on-time delivery continues to suffer. Why?

At WM Synergy, we see many manufacturers are still relying on outdated production scheduling tools that fail to reflect real-world conditions.

If your team is constantly reworking schedules, fighting fires on the shop floor, or missing customer deadlines, it’s time to rethink how you’re scheduling production.

The Problem with Traditional Finite Capacity Scheduling

For decades, manufacturers have used finite capacity scheduling software to create production plans. These systems build schedules based on known variables: machine availability, labor hours, routing times, and work center capacities. On paper, it works. But in reality, it doesn’t.

Here’s why traditional production scheduling fails:

- Machines break down unexpectedly

- Employees call in sick or don’t show up

- Materials don’t arrive on time

- Rush jobs disrupt the schedule

Every one of these events throws off your carefully planned schedule. The result? Late orders, inefficient production flow, and frustrated customers.

Worse, these systems require constant manual updates to stay accurate. Your team wastes time rescheduling jobs instead of focusing on execution and continuous improvement.

The Solution: Protected Flow Manufacturing (PFM)

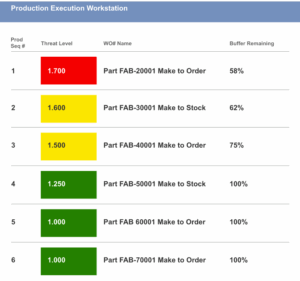

Protected Flow Manufacturing (PFM) was designed to fix the flaws of traditional scheduling systems. This software application doesn’t just schedule based on time — it uses live data to drive smarter, more agile decisions on the production floor. PFM connects directly to your ERP system and considers real-time variables like:

- Material availability

- Work order buffers

- Lead times

- Threat levels

- Shop floor disruptions

Instead of creating a rigid schedule that becomes obsolete the moment something changes, PFM produces a dynamic production execution list. It tells your team which orders to prioritize today based on what’s actually happening — not what should be happening.

Benefits of Switching to PFM

- Improve on-time delivery by prioritizing work based on real constraints

- Adapt instantly to changes on the shop floor or in the supply chain

- Eliminate constant rescheduling and reduce administrative overhead

- Enhance flow and productivity with smart buffers and proactive execution

PFM empowers your team to focus on what matters most: getting orders out the door on time, every time.

Ready to Leave Old-School Scheduling Behind?

If you’re tired of chasing problems and rescheduling every time something breaks, it’s time to consider something other than the traditional finite capacity scheduling method. Protected Flow Manufacturing represents a fresh, more responsive approach to production scheduling — one that reflects the real world of modern manufacturing.

Let’s stop scheduling like it’s 1995 (YES, that was actually 30 years ago!) and start delivering on time with a dynamic scheduling system.

Contact WM Synergy today to learn how PFM can revolutionize your shop floor and help you finally solve the late problem in manufacturing.