Manufacturers with a Quality Management System (QMS) that is integrated with their ERP system achieve greater consistency in the activities involved in product and service realization. By streamlining business processes, manufacturers can further enhance efficiency, reduce costs, and boost customer satisfaction. We can help you reduce expensive mistakes and increase efficiency by improving use of time and resources.

Improve compliance and control cost.

Today’s new breed of analytical tools and software systems employ AI (artificial intelligence) to provide predictive analytics (what will happen) and prescriptive analytics (what should be done to prevent something from happening). Taken together, these analytical capabilities can positively change how you manage your business and enable you to deliver more value to your customers.

Gain a key differentiator.

Your ERP and factory systems form a huge repository of data that can be delivered remotely to support decision making or to simply monitor activity. Our “low code/no code” mobility tools allow end users to design their solutions through easy to use interfaces.

Instant access to live information.

Our Digital Transformation tools include a robust mobility platform that puts important data at your customers’ finger tips. Building mobile experiences that provide your customers with easy to use data access or tools that simplify buying, will keep them coming back to you instead of your competition.

A Competitive Advantage

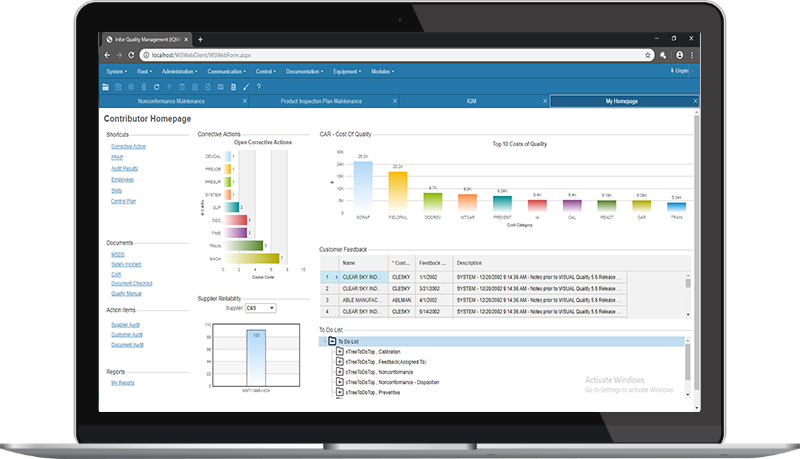

Your fully integrated QMS can monitor data from your ERP and Smart Manufacturing software in real time. It tracks critical metrics such as down time, reject rates and reasons, supplier performance, and many other crucial measures and metrics.

Key Performance Indicators

Having the right integrated QMS software solution is crucial to defining meaningful KPIs that enable your business to continuously improve and grow.

Unify Departments & Data

With QMS software, you can monitor fully integrated data from your ERP in real time. You’ll be able to track supplier performance, non-conformances, corrective actions, trends, auditing, and customer feedback.

Automate Approvals

Use your QMS software to automate sign-offs and approvals for document changes, non-conformance dispositions, corrective action completion, and more.

Industry Standard Compliance

Competing in a certain industry often requires certification. Our QMS supports many industry standards including ISO9001:2015, AS9100 and AS9102 (Aerospace), ISO 13485, cGMP – FDA 21 CFR Part 11 (Medical Device), MIL-I-45208 and MIL-Q-9858 ( Military), and ISO/TS 16949 (Automotive).

Increase Reaction Speed

Having real-time QMS software allows you to react quickly to variation from standards. Whether it’s product defects, audit findings, or customer complaints, you won’t have to wait for paper or spreadsheet reports to be updated to see an anomaly.

Our inspection data entry is 200% faster. We spend much less time on documentation and all other quality processes take 33% less time.

I am very impressed with the total quality management system, which addresses cradle to grave traceability, which is imperative in our business.

Our Infor Quality system enabled us to organize ourselves and manage the ISO 13485 certification and validation process. It would have been impossible to achieve without the software.

A feature-rich QMS option.

Non-Conformance & Corrective Action

Create/track all internal non-conformances (NC) with links to jobs/work orders and complete scrap/rework tracking. Assign Correction Actions internally to suppliers or customers.

Document Control

Managed all company records with revision, approval, distribution, and review controls, which allows for simple or complete requests for change with unlimited workflow.

Supplier Performance

QMS offers complete supplier quality management tracking, reporting, and trending, improving overall data management..

- Supplier Management: Calculate a score for each supplier based on all supplier activity in the QMS modules and miscellaneous criteria. Trend this rating over time.

- Portal: Allow selected suppliers to manage task assignments on specific QMS NCs, CPAs, Documents, and Requests via a webpage they can access with login security from any internet-enabled module, phone, tablet, or desktop.

- Non-Conformance: Create/track all supplier NCs, material return reporting, and supplier investigation/disposition steps.

- Corrective/Preventative Actions: Create/manage all supplier CPAs.

Medical Device Manufacturing

- End-to-end customer relationship, sales, purchasing, performance, and financial management

- Estimating with multiple quantity breaks

- Integrated capacity planning (Lean, TOC, JIT) with unlimited "what-if" scenarios

- Material planning with real-time visibility of demand and supply

- Cost control (actual, average, standard)

Aerospace & Defense

- Engineering with CAD integration

- Engineering change control

- Specifications and data "flow down" for ITAR, DFAR, etc.

- Actual job costing

- Project Management with Earned Value Management and milestone reporting

Automotive Manufacturing

- Configuration management

- Serial and lot control

- Design and engineering

- Capacity planning & scheduling (Lean, TOC, JIT)

- Actual costing

Industrial Manufacturing

- End-to-end customer relationship, sales, purchasing, performance, and financial management

- Estimating with multiple quantity breaks

- Integrated capacity planning (Lean, TOC, JIT) with unlimited "what-if" scenarios

- Material planning with real-time visibility of demand and supply

- Cost control (actual, average, standard)

Process Manufacturing

- Tailor-make your formulations for maximum efficiency

- QC activities management with industry-aligned compliance labeling & reports

- Precision control over batch production, including by-products

- Define and monitor losses at each stage

- Dynamic ingredient adjustment to meet product objectives

Related Products and Services

- Multi-Tenant Cloud, Dedicated Cloud, or On-Premise Deployment

- Industry Leading Configurator (CPQ)

- Dashboards & Analytics

- Mobile-Friendly

- Customer, Vendor, & End-User Portals

- Connected Business

- Rapid Integrations

- Remote Collaboration

- Business Resilience

- Future Proof

- Costing, Scheduling, & Material Planning Tools

- Fast User Adoption

- See Where Your Jobs Are

- On-Premise or Hosted Deployment

- Powered by Microsoft SQL Server Database

- Tailored for Discrete Manufacturing Industries

- Robust IBM Power System Integration

- Advanced User Architecture with Integrated Social Features

- Secure & Flexible Deployment Options

- Full-Spectrum Manufacturing Capabilities

- Quality System Assessment

- Internal Auditor Training

- Supplier Performance Management

- Corrective & Preventative Action

- Managed Services

- Digitally Manage Nonconformance Actions

- Know Quality Priorities & Tasks

- Inspect Records in Real Time

- Control Document Management

- Automate Preventative Maintenance & Gage Calibration Scheduling

- Integrated Quality Workflow

- 100 Analysis Reports

- ISO Compliance Tool

- Unlimited Attachments

- View Historical Audit Trail

Related Resources