How Visual ERP Can Help Improve Your Company’s Manufacturing Scheduling

Manufacturing scheduling is an essential cog for any company specializing in the making of goods and products. Determining when a job should go to the manufacturing floor requires not only the proper planning and supervision, but also the ability to confront problems as they occur.

But not every operation runs as fluidly as one would like. There are, at times, hiccups in production that create constraints—better known as bottlenecks. These constraints can jam up the entire process, and as a result, perpetuate wait times and ultimately wreck any and all promises of on-time delivery.

Wouldn’t it be great if you only had one job to worry about and that was it? But that’s not reality. Chances are you have dozens, if not hundreds of jobs that all require the same care, as well as individual processes and steps in your production line. Constraints occur because these jobs are often competing with one another for the same attention, the same machine or the same work center. So when two jobs show up at the same machine at the same time, one of them has to wait. When three jobs show up, two of them have to wait and so on and so on. Hence the bottleneck.

Why is all of this important? Because at the end of the day, all companies want to make money and all companies want to make their customers happy and keep them coming back for more. None of this is possible unless your manufacturing scheduling capabilities are reliable, predictable and versatile.

If you’re experiencing, or have experienced, bottlenecks within your production line and can’t seem to gain a grasp on your manufacturing scheduling—Visual ERP may be the solution you’ve been looking for. The following are just some of the ways Visual ERP can help your company improve its scheduling capabilities to ensure customer satisfaction is met and profits continue to climb.

Improve Your Manufacturing and Scheduling Capabilities With:

Proactive & Predictive Forecasting

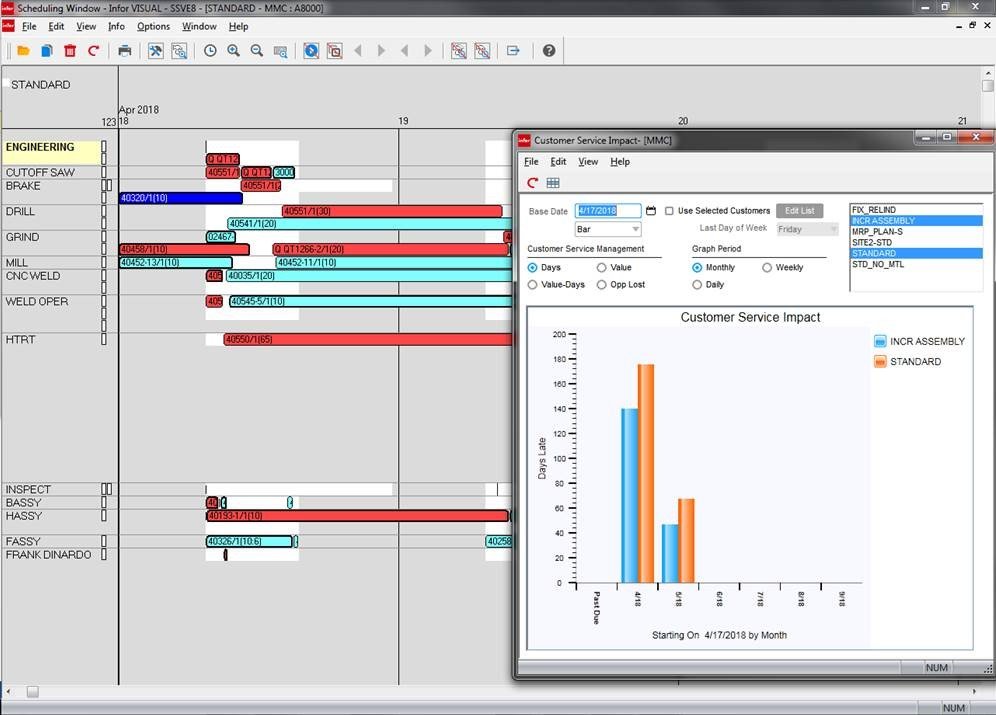

Having the foresight to anticipate problems before they arise is something most operations managers would kill for, but intuition can only take you so far. Visual ERP, implemented correctly, will proactively point out where the next constraint will occur and why.

Knowing where the bottleneck will occur days, weeks or even months from now allows you to make the needed adjustments to thwart those constraints. Common adjustments or actions to prevent bottlenecking include:

- Increase capacity at a particular machine

- Subcontract work (if necessary)

- Invest in additional infrastructure

- Stockpile materials

Taking any one or all of these actions will help you maximize throughput and prevent bottlenecks. Another great aspect of Visual ERP is that it can also tell you why you’re experiencing constraints—which makes finding solutions to these bottlenecks much more efficient and effective.

Smarter Simulations

Many ERPs display Gantt charts—which serves as a graphical representation of your production plan and shop. A Scheduling Gantt chart may allow you to manually change your manufacturing scheduling, attempting to account for other jobs or constraints, as mentioned earlier. However these ERPs, depend far too much on assumptions.

Almost every ERP, including Visual, features capabilities that allow you to manipulate manufacturing scheduling. Using a simulation mode, a user can drag and drop jobs throughout their production schedule. While this allows you to rearrange your manufacturing scheduling, it’s all based on guesswork. This is called scheduling within a black hole. It involves an ERP user making the changes they think will work, but without additional information, they have no idea the future impacts that may exist as a result of their scheduling changes.

Visual ERP brings much more certainty in the drag and drop method. Visual lets you see what, if any, constraints you’ve created down the line as a result of your scheduling change. Visual ERP also allows a user to simulate adjustments to see any and all impacts in the production scheduling. For instance, it allows you to simulate what your production line would look like if you decided to increase capacity on any given machine.

Visual ERP is a game changer when it comes to your manufacturing scheduling—take a look at some of these case studies and see for yourself. It creates certainty and transparency in an industry rooted in customer satisfaction. But what Visual ERP really does is help you enhance your throughput and increase on-time delivery so you can achieve increased production without increasing overhead.

Uniquely, Visual will also take profitability into account during all simulations—letting you know if the juice is worth the squeeze, so to speak. It allows you the insight to know whether increasing on-time delivery is actually cost effective in terms of the overhead it requires and vice versa. Visual will tell you the exact cause of your bottlenecks, how you will increase throughput, and therefore positively impact your bottom line.

At Synergy Resources, we believe Visual ERP is not a business solution; it’s THE business solution. Contact us today to learn more about how manufacturing scheduling capabilities with Visual ERP can increase throughput without increasing overhead.