To be successful in today’s “instant gratification” marketplace, it’s crucial to always have the right products and materials on hand to fulfill customer demand. Demand Driven Material Requirements Planning (DDMRP) is an innovative production planning and inventory control system that unites the best of Lean Manufacturing, Theory of Constraints (TOC), and Six Sigma principles to ensure you’ll always have optimal inventory levels — never carry too much and never run out. This eliminates the cost of excess inventory and lost sales due to out-of-stocks.

Never make too much of anything again!

DDMRP’s re-supply recommendations are based on actual consumption — you only make what customers are buying. This ensures that you won’t have a surplus of products and that your supply won’t run out.

End expedited shipping and overtime.

Costly overtime and expedited shipments are eliminated with DDMRP because what is needed to meet customer demand is always available. This also provides you with a lead-time edge that enables you to beat out competitors.

Bring Scheduling and Visiblity to Any ERP.

DDMRP simplifies material requirements planning and removes reactive drama from day-to-day inventory management in your existing ERP solution.

Deliver on time.

Having what customers want on hand significantly improves on-time delivery, which helps create loyal customers while reducing time-pressure related workplace tension.

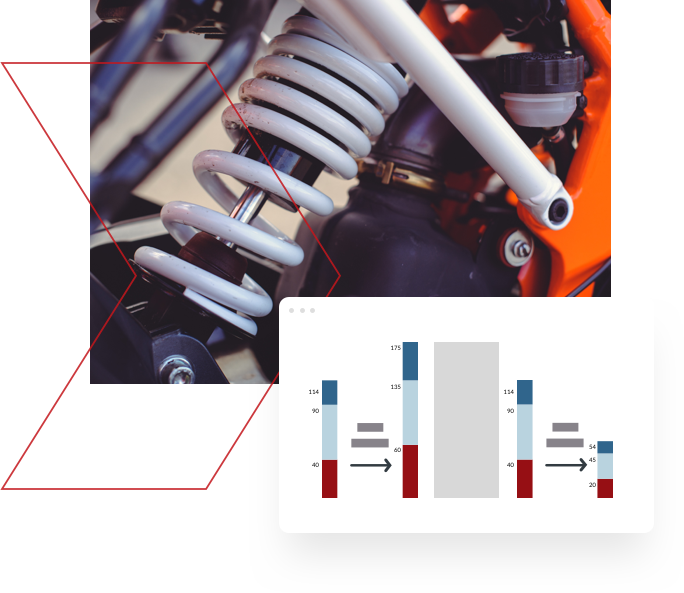

Carry Less Inventory and Never Run Out

No one is in the business of carrying too much inventory. It’s requires costly space, handling, and can go obsolete quickly. DDMRP allows you to reduce inventory, yet always meet your customer or production commitments.

Free Up Money

As DDMRP aligns your production and purchasing with the real needs of your customers, you will end the common practice of overstocking. Less goods in inventory means more money available for strategic initiatives.

Build Customer Trust

At the heart of DDMRP is its constant look at what and when the customer is buying. You no longer need to guess at this and try to forecast what will happen. Using DDMRP will increase your fill rates, which in turn increases customer satisfaction and loyalty.

Strengthen Your Supply Chain

Your relationships with your vendors and customers will be stronger when you are providing accurate information that can be trusted. You will no longer be placing orders only to have to come back and change them up or down.

Synchronize Your Sub Assemblies

You can’t finish a product unless all the parts are there. DDMRP ensures that all parts are completed when needed. Using “Elastic Due Dates”, DDMRP continually adjusts interrelated work order due dates as manufacturing or customer conditions change.

Stay in Front of Production Problems

Production stops when material shortages occur. Just like a customer, the production floor demands that material be available on time. DDMRP, balances both customer and production demand in real time and ensures that material is stocked for both.

We implemented Protected Flow Manufacturing (PFM) in 2017 for its Demand Driven Material Requirements Planning (DDMRP) functionality and the surrounding features of LillyWorks. PFM suited our Enterprise Resource Planning (ERP) needs. PFM is a great all-around fit for our company. Our biggest concern was our raw material supply chain management and as a mature startup, we are aggressively growing which means things change for us rapidly. The DDMRP component and the way that PFM handles the order points and buffers in real-time, on the fly, is exactly what we need. We import our customer forecasts and utilize the historical demand which resizes our buffers automatically; order points are magically moved as needed and safety stock is handled perfectly by PFM every time without issues. PFM supports our rapidly growing company and is worth it! My advice to any manufacturer looking at PFM would be to get educated on DDMRP, compare it to traditional MRP, and once you have determined it is the right fit for your company, go with LillyWorks PFM.

We now manage 70% of our materials (by $ value) for manufacturing and customer service under DDMRP. We started our pilot program in April and have been fully implemented since Mid-May. Our average lead time to our customer has been reduced 11 days to 2.2 days, while also realizing a 3% reduction in inventory investment.

Running out of inventory items at the worst possible time – a common result of executing a plan based on forecasting– is eliminated by DDMRP, Mr. Lilly said. These DDMRP features, are embedded in our ERP system or can work in tandem with any existing ERP system already installed, make sure the manufacturer never runs out of critical inventory items.

With DDMRP we have nearly eliminated expedites. Our inventory is down by 25% in four months and we have no Stocks Outs.

with DDMRP

stock required for production

Consumption Based Ordering

Manufacturers traditionally try to forecast what future consumption will be. Inaccurate forecasting can therefore instruct manufacturing plants to over or under produce what is really needed. DDMRP dynamically looks at the changes in demand and adjusts the supply orders accordingly. This results in just the right amount of inventory for both product items and customer end items.

Buffers Inventory Levels Up & Down the Supply Chain

DDMRP understands the dependencies of inventory at every level of manufacturing. Raw materials supply material to sub assemblies. Sub assemblies are needed for higher assemblies and customer end items. The levels of stock from raw material through upper level assemblies and finished goods need to be optimized so that no stockouts occur. Today’s MRP systems address this by creating static material plans and then issuing “exceptions” to planners who have to manually make adjustments. DDMRP makes these adjustments automatically as consumption conditions change.

Improved On-Time Delivery

The only way to deliver on time is to make sure that you have all of the material to make your product. Stockouts at any level of the supply chain or manufacturing process can leave you with no time to make the product for delivery. By monitoring all material demand and supply in real time, DDMRP anticipates potential material problems and adjusts inventory before problems arise.

Automotive Manufacturing

- Configuration management

- Serial and lot control

- Design and engineering

- Capacity planning & scheduling (Lean, TOC, JIT)

- Actual costing

Oil & Gas

- Strengthen Your Supply Chain

- Sophisticated Project Management

- Connect Service Efforts to Operations

- Localization & Financial Accounting Visibility

Furniture & Fixtures

- Industry Expert Partners

- Increase Quote Win Rate

- Improve Planning & Scheduling

- Cut Operational Costs

- Shorten Product Development Lifecycles

Industrial Manufacturing

- End-to-end customer relationship, sales, purchasing, performance, and financial management

- Estimating with multiple quantity breaks

- Integrated capacity planning (Lean, TOC, JIT) with unlimited "what-if" scenarios

- Material planning with real-time visibility of demand and supply

- Cost control (actual, average, standard)

Medical Device Manufacturing

- End-to-end customer relationship, sales, purchasing, performance, and financial management

- Estimating with multiple quantity breaks

- Integrated capacity planning (Lean, TOC, JIT) with unlimited "what-if" scenarios

- Material planning with real-time visibility of demand and supply

- Cost control (actual, average, standard)

Process Manufacturing

- Tailor-make your formulations for maximum efficiency

- QC activities management with industry-aligned compliance labeling & reports

- Precision control over batch production, including by-products

- Define and monitor losses at each stage

- Dynamic ingredient adjustment to meet product objectives

Related Products and Services

- Seamless Integration

- Easy To Set Up. Easy to Maintain

- PFM Anticipates Issues

- See the Future Before it Happens

- Large & Small Jobs Are Optimized

- Scheduling That Actually Works

- Expedited Quote to Cash

- Eliminate Future Issues

- Dynamic Material Planning

- Quick Implementation

- Organize your data by time period

- Drill down to see detail of summarized or grouped data

- Easy filtering tools

- Self-service reporting means reports when you want them not when a report writer can get to them

- Real time Dashboards, Pivots, Reports, Charts with automatic drill downs

- Front Office Productivity Gains

- Shop Floor Productivity Gains

- Inventory & WIP Reductions

- Lead Time Reductions & On-Time Delivery Gains

- Cost of Quality Reductions

Related Resources