SourceDay automates all supplier collaboration within a single, unified interface. This creates mutual visibility and accountability between buyers and suppliers.

Say goodbye to endless emails, spreadsheets & phone calls.

Rather than chase down changes and update spreadsheets, collaborate with suppliers via SourceDay’s online platform. You’ll save time, eliminate errors, avoid surprises, and always get the right parts, at the right price, at the right time.

Never spend more than necessary to ship finished goods on time.

SourceDay removes AP bottlenecks and helps reduce safety stock, so you can prevent overpayment and cut expedite fees. This frees up working capital and drives more cash to your bottom line.

Change your culture from repetitive tasks to strategic improvements.

With SourceDay, you can spend more time on strategic improvements to your supply chain by reducing repetitive daily tasks.

Automatically Update Your ERP with Accurate Prices & Delivery Dates

SourceDay can integrate with any ERP to keep your RFP, PO, vendor acknowledgements, pricing, and more in one central repository.

Know When Material Will Arrive

SourceDay provides up-to-the-minute status on every purchase, so you can skip the phone calls and emails to find out when your material will arrive.

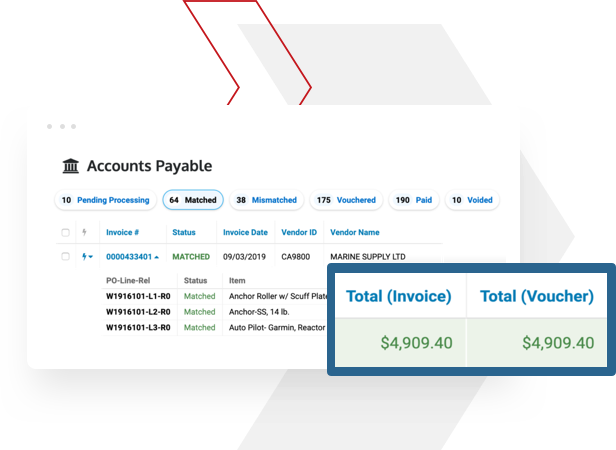

Accounts Payable Three-Way Match From the Source

SourceDay automatically knows your PO price, how much was received and when, and even what you’re being invoiced for. This ensures that your accounts payable is accurate and ready to be paid.

Affordably Manage Your Supplier Base

As your business grows, so will your supplier base. SourceDay makes it easy to support more suppliers with the same number of buyers, so you don’t have to worry about added costs.

Maximize Supply Chain Performance

Supply chain efficiency is key to your success. Access the latest supply chain performance data so you can collaborate with your suppliers to drive efficiency.

Simplify Onboarding Suppliers

SourceDay’s team of professionals are here to help you achieve exceptional communication and collaboration, so that you and your suppliers are always on the same page.

We liked that SourceDay could automate our purchasing processes and free up our buyers to do more proactive work. We want our buyers to spend more time on problem solving or addressing process issues. We also want to grow our vendor base and improve our vendor relationships.

SourceDay has easily saved me 10+ hours a week with purchase order updates, tracking orders, and emails regarding orders. I can see what vendors acknowledged and get a complete history on every part and PO.

SourceDay gives us a central hub to manage POs without having to go to multiple systems and automates notifications to reduce missing any orders. It’s a one-stop-shop for not only managing orders but enabling efficient communication between the buyer and supplier.

It was fairly straight forward to implement the solution in parallel with our upgrade. The folks from SourceDay covered the integration to the Infor ERP, the training of our Procurement staff and the on-boarding of our Vendors. The SourceDay solution simplifies our Vendor RFQ and Procurement processes and saves us significant amount of time on a daily basis.

Gain a 360-degree view of your suppliers in an integrated SaaS solution.

Request for Quote

SourceDay streamlines the RFQ process by automatically generating a unified view of each supplier that responded and their best offer. This enable you to make more informed decisions without the manual effort.

Purchase Order Collaboration

Digitize and standardize communications between your procurement team and your supply chain and automatically feed real time exceptions, such as lead times, pricing, quantities, and delivery dates, directly into your ERP.

Accounts Payable Automation

Automatically match vendor invoices to purchase orders and receipts to take advantage of discounts, reduce labor costs, and ensure that you never overpay.

Aerospace & Defense

- Engineering with CAD integration

- Engineering change control

- Specifications and data "flow down" for ITAR, DFAR, etc.

- Actual job costing

- Project Management with Earned Value Management and milestone reporting

Industrial Manufacturing

- End-to-end customer relationship, sales, purchasing, performance, and financial management

- Estimating with multiple quantity breaks

- Integrated capacity planning (Lean, TOC, JIT) with unlimited "what-if" scenarios

- Material planning with real-time visibility of demand and supply

- Cost control (actual, average, standard)

Electronics & High-Tech

- Alternate item on bill of materials (BOM)

- Item cross reference (supplier and manufacturer)

- Approved vendors and manufacturer lists

- Supply chain visibility with Web based portals

- Reference designators

Automotive Manufacturing

- Configuration management

- Serial and lot control

- Design and engineering

- Capacity planning & scheduling (Lean, TOC, JIT)

- Actual costing

Industrial Machinery & Equipment

- Win More Business

- Meet Customer Delivery Expectations

- Increase Velocity of Spare Part Sales

- Collaborate With Suppliers & Customers

- Leave Your Competitors Behind

Related Products and Services

- Multi-Tenant Cloud, Dedicated Cloud, or On-Premise Deployment

- Industry Leading Configurator (CPQ)

- Dashboards & Analytics

- Mobile-Friendly

- Customer, Vendor, & End-User Portals

- Costing, Scheduling, & Material Planning Tools

- Fast User Adoption

- See Where Your Jobs Are

- On-Premise or Hosted Deployment

- Powered by Microsoft SQL Server Database

- Connected Business

- Rapid Integrations

- Remote Collaboration

- Business Resilience

- Future Proof

- Improve Manufacturing Efficiency

- Reduce Production Waste

- Track & Analyze Downtime in Real-time

- Instant Notifications for Shop Floor Workers

- Improve Operator Engagement & Communication

- Software & Process Validation - “Verifiable” & “Non-Verifiable”

- Design Validation

- Equipment Qualification

- Auditing – Internal/Supplier

- PPAP - Support

- Increase Inventory Accuracy

- > 40% Reduction in WIP

- Inventory Reduction

- On-Time Delivery Gains of > 25%

- Lead Time Reduction > 20%

- Be More Competitive

- Increased Cash Flow

- Repeat Customers

- Improve Production Quality

- Less Inventory, More Cash

- Maximize the operational efficiency of equipment (OEE)

- Empower operators to help maintain their equipment

- Realize an increase in up time, reduce overall cycle times

- Eliminate defects

- Improve productivity and safety

- Improved responsiveness to customer demand

- Enable more frequent product changes

- Smoother, faster startups

- Lower inventory levels

- Lower manufacturing cost