Acumatica Manufacturing ERP Software Is a Cut Above the Rest

When you work as hard as you do in the manufacturing world, dependable software is vital to ensuring your company continues to thrive. Acumatica manufacturing software provides the tools necessary to operate consistently, please customers and protect your bottom line. Experts at WM Synergy recommend Acumatica ERP for manufacturing, as the platform is intuitive compared to competing solutions on the market.

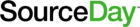

Pay attention to the fine details surrounding your manufacturing company with software that accommodates unlimited users. You can access the data you need for control and calculated planning from anywhere.

See the real-time data you’re after on the mobile devices you already own for your manufacturing organization. You’ll have around-the-clock access to an economical platform that doesn’t require you to spend more to expand your company and add more users down the road.

Stay informed about your supply chain and cash flow. Many of our customers incorporate Acumatica software for manufacturing to follow through with customer orders, manage sales, monitor inventory numbers, review spending reports and identify where cost-cutting measures are necessary.