MachineMetrics is the industry’s first AI-driven machine monitoring and predictive analytics platform for discrete manufacturers and machine builders. Its award-winning Industry 4.0-ready solutions work out-of-the-box to increase equipment productivity and efficiency through edge connectivity, real-time visibility, deep manufacturing analytics, and AI-driven predictive and prescriptive alerts. By simplifying Industrial IoT, MachineMetrics enables customers to digitize and drive decisions with machine data.

MachineMetrics Production

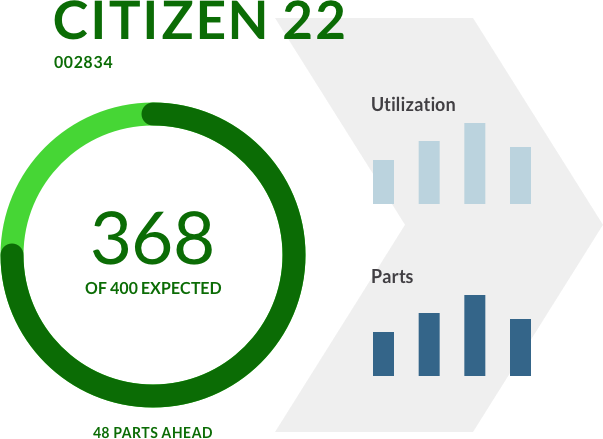

Empower operators, production managers, and executives to reduce bottlenecks with real-time production visibility, OEE, and downtime analysis.

MachineMetrics Health

Allows maintenance managers and process engineers to keep machines running with real-time condition monitoring, so diagnoses can happen when they’re needed and predictive maintenance can prevent machine downtime.

Built & Priced for Everyone

Transforms the ability of OEMs and equipment providers to service customers by remotely monitoring machines, reducing on-site service calls, and providing preventative and predictive maintenance.

How MachineMetrics works.

Connect With & Capture Data

MachineMetrics is an easy to implement platform for connecting to and capturing data from any piece of discrete manufacturing equipment, regardless of brand or age. MMEdge Gateway enables secure ethernet, WiFi, and cellular communication while connecting directly to machine tool PLCs and controls. Add your own sensors or connect legacy equipment with digital and analog I/O that is configured and managed remotely through a web interface.

Out-of-the-Box Visualizations & Analytics

Encrypted data is streamed to the secure MachineMetrics cloud where the data is structured and aggregated to enable out-of-the-box visualizations and analytics. Access to historical and real-time data is available through open APIs. Real-time dashboards, historical analysis, and integrations with other systems can be built with these APIs.

Real-Time Monitoring

The analytics engine will monitor machine condition and other manufacturing data and initiate an action, such as text notifications when a monitor is triggered. A rules engine is provided for deploying monitors based on machine condition data and patent pending advanced machine learning algorithms can be deployed for detecting anomalous behavior.

FAQs

How does MachineMetrics support digital transformation?

MachineMetrics enables manufacturers to move from manual, reactive operations to data-driven, proactive decision-making. By automatically collecting machine data, analyzing performance trends, and delivering real-time alerts, the platform helps teams act quickly to resolve issues. This leads to improved machine utilization, better scheduling, and higher throughput. For manufacturers looking to embrace Industry 4.0 and smart factory principles, MachineMetrics provides a practical starting point for digital transformation.

What problems does MachineMetrics solve for manufacturers?

Many manufacturers struggle with machine downtime, underutilization, and a lack of visibility into shop floor operations. MachineMetrics solves these issues by:

- Reducing unplanned downtime through predictive insights.

- Improving machine utilization rates with real-time monitoring.

- Automating manual reporting, saving time and eliminating errors.

- Helping managers identify bottlenecks and inefficiencies.

With greater visibility, companies can increase throughput, reduce costs, and maximize ROI from existing equipment.

How does MachineMetrics work?

MachineMetrics connects directly to CNC machines, legacy equipment, and other shop floor assets through sensors and IoT devices. It automatically captures key production data such as cycle times, downtime events, and part counts. This data is then analyzed by the platform’s cloud-based system, which delivers real-time dashboards, reports, and alerts. Operators, managers, and executives can use these insights to make faster, better decisions that improve performance across the factory.

What are the measurable benefits of using MachineMetrics?

Companies using MachineMetrics have reported impressive results, including:

- $1M+ in additional annual capacity gains.

- 20% increases in machine utilization.

- 29.7% reduction in downtime events.

By unlocking hidden capacity and improving efficiency, MachineMetrics enables manufacturers to increase profitability without major capital investments in new equipment.

How does MachineMetrics improve real-time visibility?

MachineMetrics provides real-time dashboards that show the status of every connected machine. Operators receive instant feedback on performance, while managers can monitor utilization, downtime, and quality metrics across the shop floor. This visibility allows teams to identify problems as they happen, rather than after production has already been impacted. The result is a more agile, responsive manufacturing operation.

Is MachineMetrics compatible with different types of equipment?

Yes. MachineMetrics is designed to work with both modern CNC machines and older, legacy equipment. Its flexible connectivity solutions allow manufacturers to capture data regardless of machine type or brand. This makes it ideal for mixed-production environments where different generations of equipment coexist. By standardizing machine data, MachineMetrics provides a unified view of performance across the entire factory.

How does MachineMetrics support industries like aerospace and defense?

In highly regulated industries such as aerospace and defense, precision, traceability, and compliance are critical. MachineMetrics helps companies in these sectors monitor production performance, reduce downtime, and ensure consistent quality. Real-time machine data supports compliance reporting, predictive maintenance, and higher overall equipment effectiveness (OEE). This allows manufacturers to meet strict standards while also improving efficiency and profitability.

What role does MachineMetrics play in predictive maintenance?

MachineMetrics uses machine data to identify performance trends and anomalies that may indicate upcoming failures. This predictive capability allows manufacturers to schedule maintenance before breakdowns occur, reducing costly unplanned downtime. By shifting from reactive to proactive maintenance, companies can extend equipment life, reduce repair costs, and improve reliability across their production assets.

How can WM Synergy help companies implement MachineMetrics?

WM Synergy partners with manufacturers to integrate MachineMetrics into their operations as part of a broader digital transformation strategy. We provide consulting, implementation, and optimization services to ensure companies capture the full value of machine monitoring. Our team helps align the technology with business goals, train employees, and connect MachineMetrics with ERP systems for end-to-end visibility. With WM Synergy, manufacturers can accelerate their digital journey and maximize ROI from MachineMetrics.