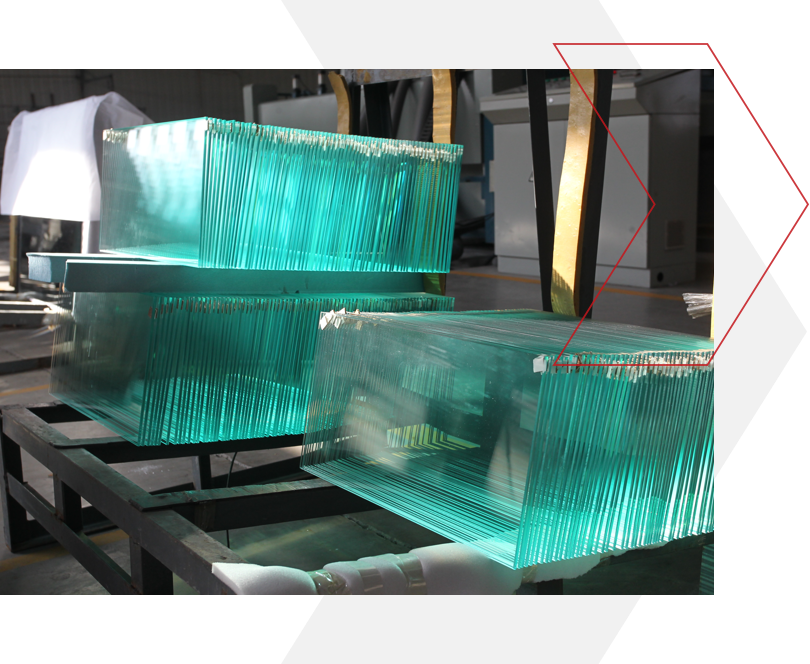

Sustain quality, cost, and delivery at a profit with a metal fabrication ERP.

WM Synergy’s metal fabrication ERP can help you improve your people, processes, and technology. Our purpose-built ERP system will enable you to successfully overcome industry challenges, economy-driven cyclical demand patterns, and continuously increasing customer expectations, all while managing capital requirements.